VISION LASER offers state-of-the-art laser processing for brazed diamond tools – developed for maximum precision and efficiency in tool production. Based on the proven HELITRONIC VISION, the machine combines decades of experience with pioneering laser technology.

Thanks to the innovative C.O.R.E. operating system, you benefit from intuitive operation, seamlessly integrated system applications and a fully digital workflow – standardised on all machines from the UNITED GRINDING Group.

Features

Mineral casting portal design

The VISION LASER features the WALTER mineral casting portal design for optimum tool surfaces. The machine therefore offers you optimum vibration damping, temperature insensitivity, drive dynamics and, ultimately, grinding precision.

Linear and torque drives

All five CNC axes of the VISION LASER are equipped with linear drives and are controlled by integrated high-resolution measuring systems. These generate precise movements with high dynamics. The VISION LASER also has a C-axis with torque drive for maximum accuracy and durability.

Automatic calibration

Precision made easy. Automatic calibration of the axes, the laser focus position, and the center of rotation minimizes operator effort and enables highly precise and efficient manufacturing processes.

Sustainability

Continuous monitoring of machine consumption data such as air consumption, energy consumption, laser and scan head, and temperature monitoring. No need for cooling lubricants, filters, or wires, which reduces resource consumption and operating costs.

Software integration and user-friendly operation

The GTR ProfDia Laser software is used as a classic application similar to the GTR ProfDia Erosion, which has been widely used in wire erosion for decades and thus offers GTR-experienced users an easy introduction to operating the new laser machine.

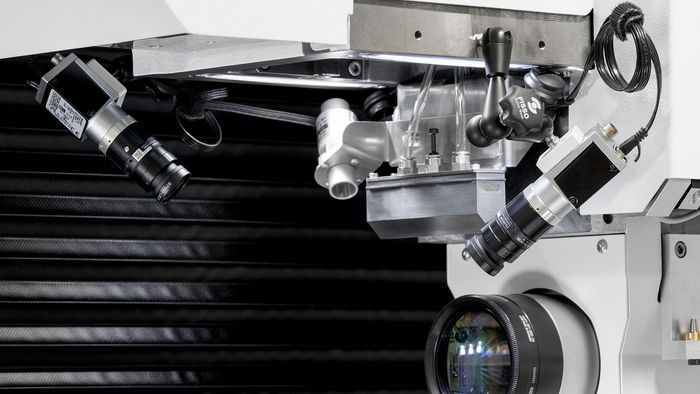

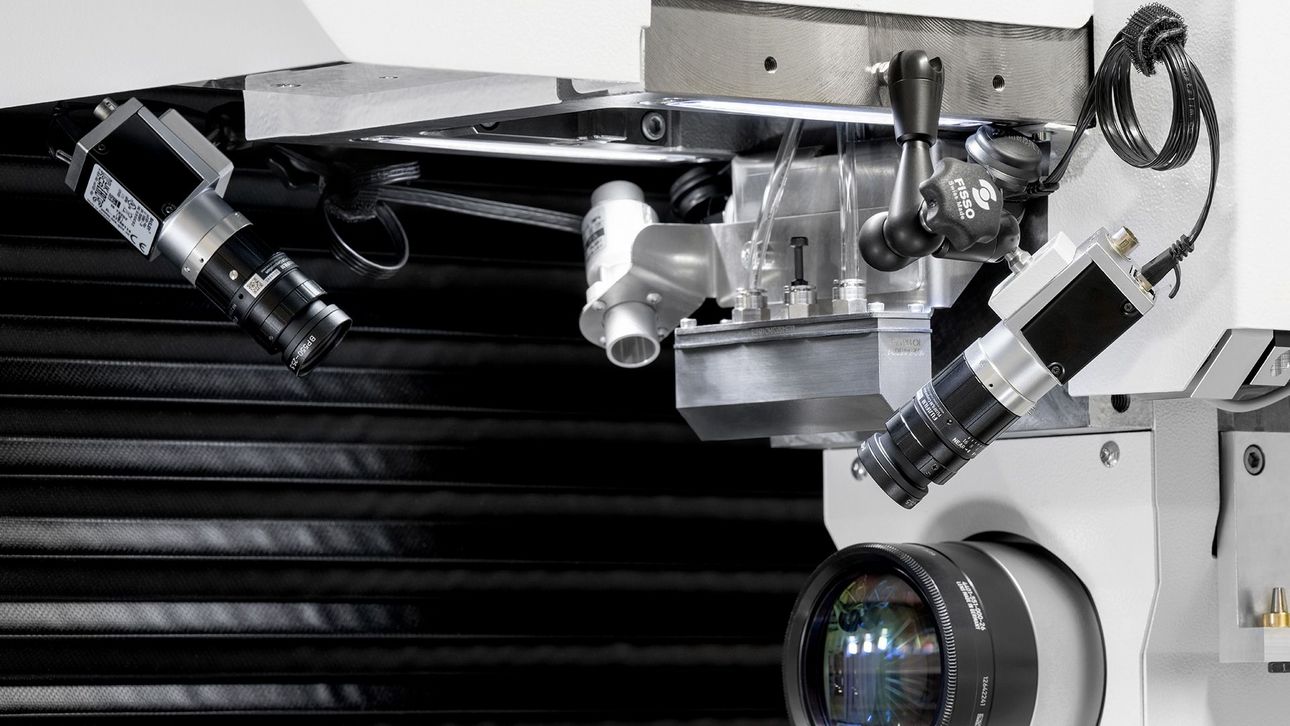

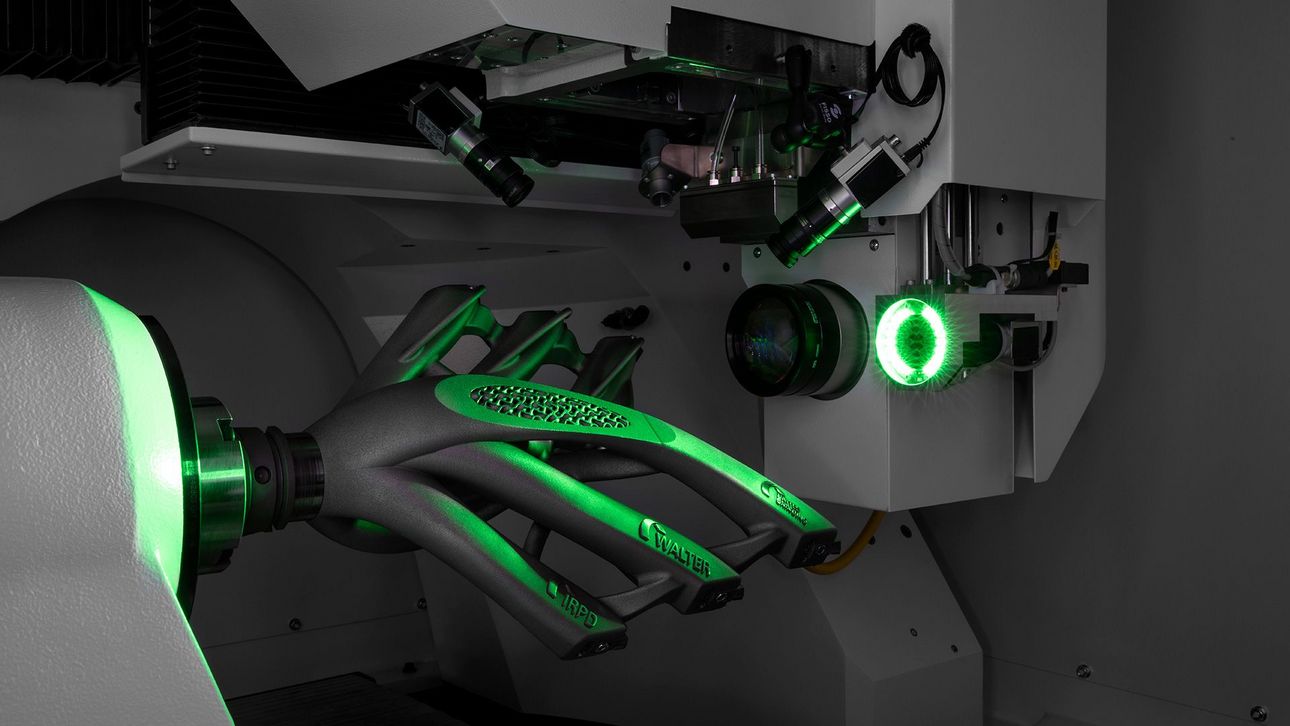

Live process cameras (optional)

Für das Einmessen der Rohlinge und für die Überwachung der Bearbeitung sind optional drei Kameras verfügbar, die den Bearbeitungsprozess in einer Übersicht oder einzeln im Vollbildmodus anzeigen können.

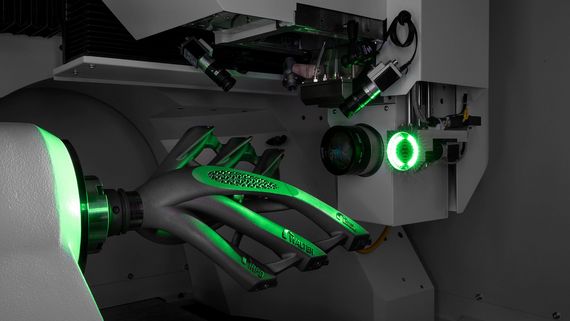

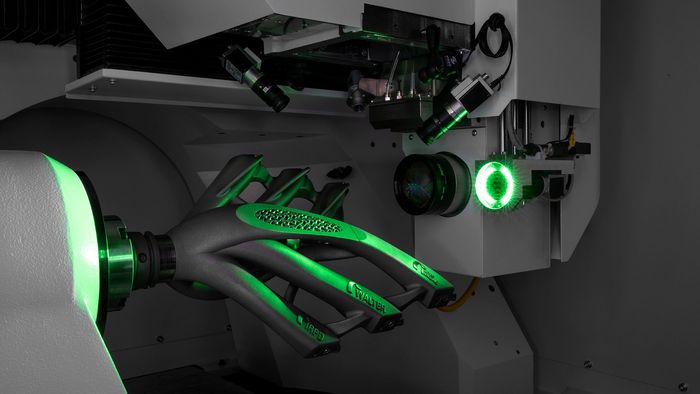

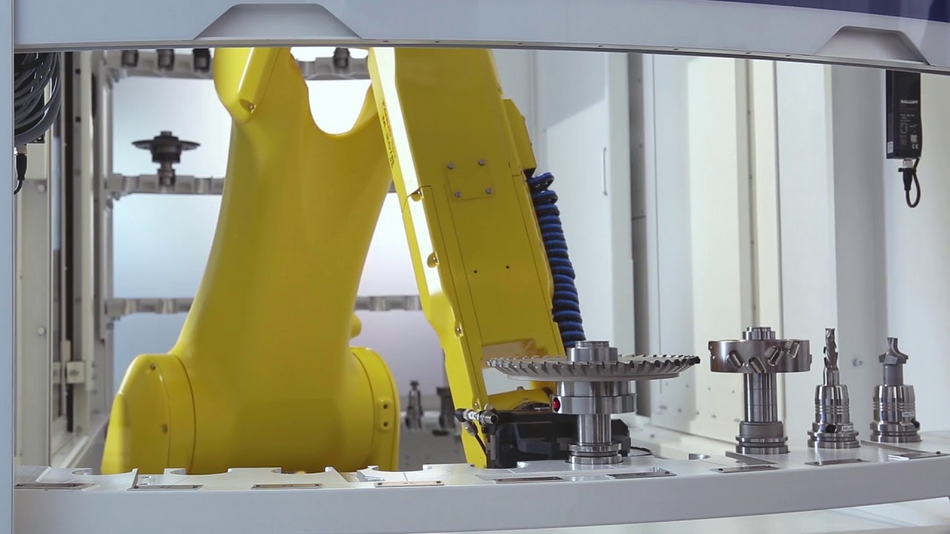

Automation with Robot Loader 25 (optional)

Folded-arm robot with 6 controlled axes for automatic loading of tools. User-friendly “Process Manager” software for convenient programming of loading operations and intelligent management of tool magazines. Automatic teaching enables short setup times. Depending on the type of workpiece or workpiece diameter, up to 70 workpieces can be loaded via the robot loader. Maximum workpiece weight: 20 kg; maximum workpiece diameter: 250 mm